Type

|

Technical indicators

|

Remark

|

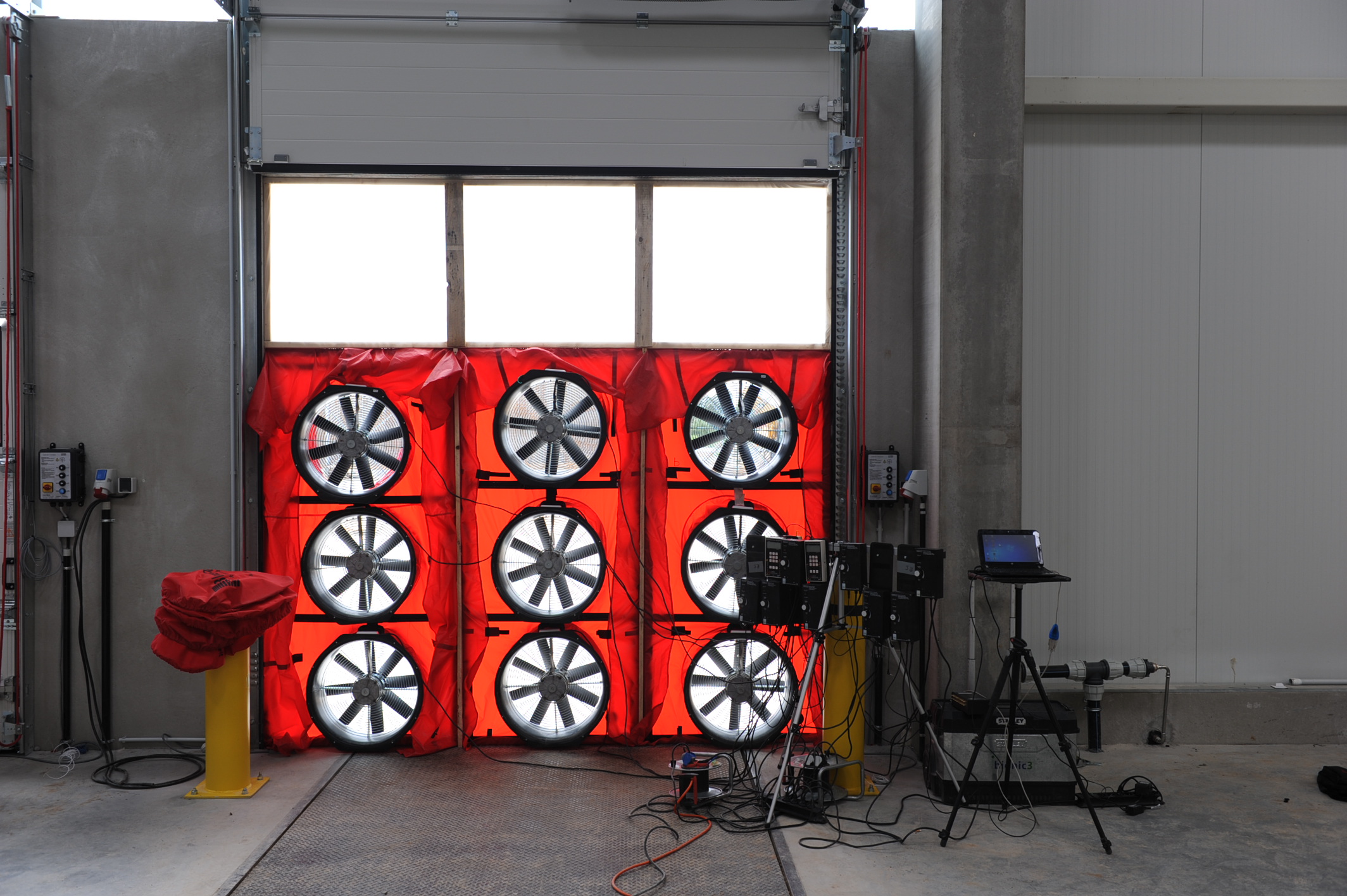

Blower (fan):

|

Maximum flow rate (230V/50Hz)

|

10,700 m3/h at atmospheric pressure (2,973 l/s, 6,300 CFM)

|

|

9,090 m3/h (2,524 l/s, 5,350 CFM) at 50 Pa

|

|

8,495 m3/h (2,360 l/s, 4,900 CFM) at 75 Pa

|

|

minimum flow

|

300 CFM with B flow ring (141 l/s, 510 m3/h)

|

|

144 m3/h with C flow ring (40 l/s, 85 CFM)

|

|

51 m3/h with D flow ring (14 l/s, 30 CFM)

|

|

18 m3/h with E flow ring (5 l/s, 11 CFM)

|

|

diameter

|

50 cm

|

20 inches

|

thickness

|

25 cm

|

10.25 inches

|

weight

|

15 kg (with flow rings A and B)

|

|

Flow accuracy

|

±3% (D/E ring ±4% or 1 CFM)

|

|

power

|

Maximum power 1KW

|

3/4 hp

|

Standards compliant

|

Conforms to ASTM Standards E779, E1554, CGSB-149.10-M86, EN 13829, ISO 9972, ATTMA Technical Standard 1, NFPA 2001, RESNET, and USACE.

|

|

Fan speed controller:

|

Power requirements:

|

220V 50Hz

|

|

shell material

|

anodized aluminum

|

|

Shell Dimensions:

|

11.5x 6.6 x4.3cm (WxHxL)

|

|

Power Cord Length:

|

about 3.6m

|

|

Fan cable length:

|

about 2.9m

|

|

Door frame and door cloth

|

frame material

|

Extruded Aluminum

|

|

width

|

71cm-101cm

|

28~40 inches

|

high

|

132cm-244cm

|

52~96 inches

|

door cloth material

|

Heavy coated nylon with clear window

|

|

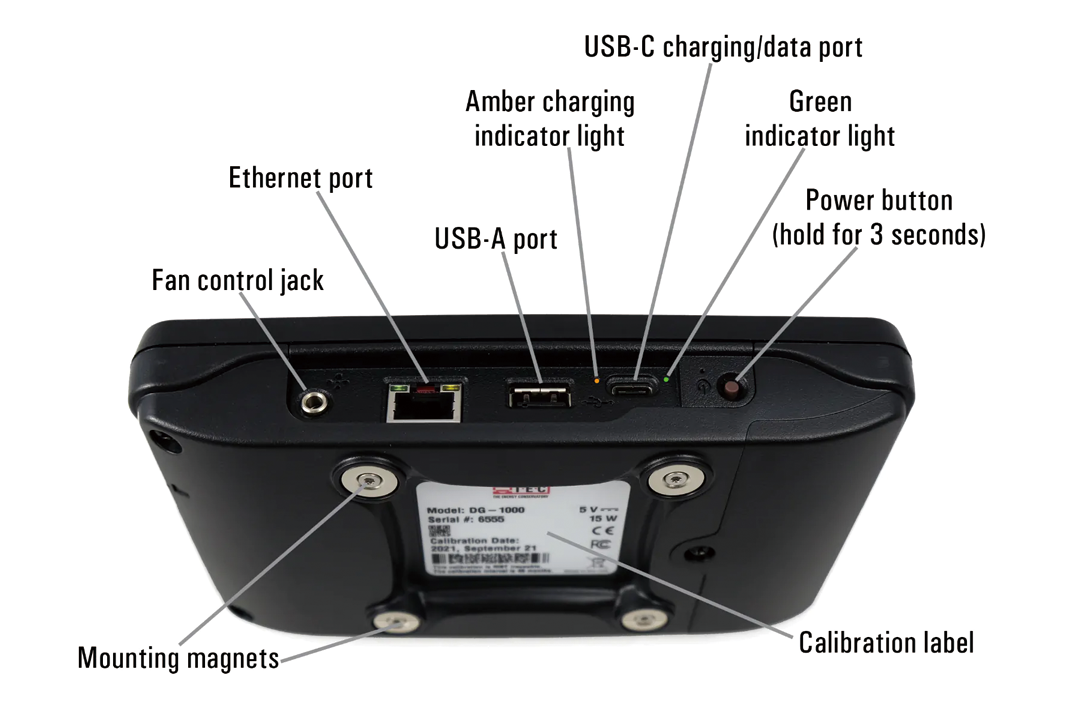

DG-1000 Digital Pressure Gauge:

|

Number of independent pressure channels

|

2 channels

|

|

pressure range

|

-2,500~+2,500 Pa (-10~+10 inches of water column)

|

|

Display resolution

|

Pa @ 0-999.9 Pa

1 Pa @ >1000 Pa

|

|

Accuracy Under Typical Use Conditions

|

0.9% of reading or 0.12 Pa, whichever is greater

|

|

unit of measurement

|

Channel A - Pa, inches of water

|

|

Channel B – Pa, inches of water, CFM,

|

|

auto zero

|

Once started, every 10 seconds

|

|

time averaging

|

1, 5, 10 seconds and long term (continuously updated)

|

|

range of working temperature

|

5~46℃

|

42~115℉

|

storage temperature range

|

-20~60℃

|

-4~140℉

|

display screen

|

480 x 272 pixels, 3.75 x 2.125 inches, capacitive touchscreen

|

|

display backlight

|

User Adjustable - Default 40%

|

|

Battery

|

Two 18650 lithium-ion batteries, replaceable

|

|

Battery Life

|

More than 15 hours of continuous use at default settings

|

|

auto shut off

|

10 minutes ~ 2 hours adjustable

|

|

supported language

|

English, German, Spanish, French, Italian, Norwegian, Dutch, Portuguese, Chinese |

|

| size |

17.8 x 10.6 x 3.5cm |

7.0 x 4.2 x 1.4 inches |

| weight |

445g |

15.7 oz |

| Standards compliant |

Conforms to ASTM Standards E779-03, E1554-07, CGSB-149.10-M86, EN 13829, ISO 9972, ATTMA Technical Standard 1, NFPA 2001, RESNET, and USACE. |

|

| Recommended Calibration Interval |

four years |

|

TECTITE Express 5.0 PC software (applicable to single fan system)

TECTITE Express 5.0 PC software (applicable to single fan system)